Difference between revisions of "Leather"

m |

|||

| (One intermediate revision by one other user not shown) | |||

| Line 30: | Line 30: | ||

In Thailand, sting ray leather is used in wallets and belts in the same way as regular bovine leather. Sting ray leather is as tough and durable as hard plastic. | In Thailand, sting ray leather is used in wallets and belts in the same way as regular bovine leather. Sting ray leather is as tough and durable as hard plastic. | ||

===In Amtgard=== | ===In Amtgard=== | ||

| − | In Amtgard leather is is used to create many of the things we use on a day to day basis. [[Belts]] are typically made of leather, although they can be [[Macrame Belt|woven]]. | + | In Amtgard leather is is used to create many of the things we use on a day to day basis. [[Belts]] are typically made of leather, although they can be [[Macrame Belt|woven]]. [[armor|Armor]], [[shoes]], [[garb]], [[Quiver]], [[Shield]] [[Covers]] and [[belt pouches]] can also made with leather. It is a common feature to [[Arts and Sciences]] competitions. [[Tooling leather]] is particularly popular. |

====Leather Crafts==== | ====Leather Crafts==== | ||

*[[Leather Tooling]] | *[[Leather Tooling]] | ||

| Line 58: | Line 58: | ||

[[Category:Amtgard Resources]] | [[Category:Amtgard Resources]] | ||

[[Category:Armor Terms]] [[Category:Arts and Sciences]] [[Category:Materials]] | [[Category:Armor Terms]] [[Category:Arts and Sciences]] [[Category:Materials]] | ||

| + | [[Category:Unformatted Resources]] | ||

Latest revision as of 13:32, 23 October 2017

Leather is a material created through the tanning of hides and skins of animals, primarily cattlehide. The tanning process converts the putrescible skin into a durable, long-lasting and versatile natural material for various uses.

Together with wood, leather formed the basis of much ancient technology. The vast majority of leather is sold according to its area. The leather is placed through pin-wheel or electronic measuring machines and its surface area is determined. The unit of measurement is square meter, square decimeter or square foot. The thickness is also important, and this is measured using a thickness gauge (the unit of measurement is millimeters, e.g., 1.8 mm is a standard thickness for a school shoe).

In some parts of the world, top-grain thicknesses are described using weight units of ounces. Although the statement is in ounces only, it is an abbreviation of ounces per square foot. The thickness value can be obtained by the conversion: 1 oz/ft² = 1/64 inch (0.4 mm)

Hence, leather described as 7 to 8 oz is 7/64 to 8/64 inches (2.8 to 3.2 mm) thick. The weight is usually given as a range because the inherent variability of the material makes ensuring a precise thickness very difficult. Other leather manufacturers state the thickness directly in millimeters.

Types of preserved leathers

Vegetable-tanned leather is tanned using tannin (hence the name "tanning") and other ingredients found in vegetable matter, tree bark, and other such sources. It is supple and brown in color, with the exact shade depending on the mix of chemicals and the color of the skin. It is the only form of leather suitable for use in leather carving or stamping. Vegetable-tanned leather is not stable in water; it tends to discolor, and if left to soak and then dry it will shrink and become less supple and harder. In hot water, it will shrink drastically and partly gelatinize, becoming rigid and eventually brittle. Boiled leather is an example of this where the leather has been hardened by being immersed in hot water, or in boiled wax or similar substances. Historically, it was occasionally used as armor after hardening, and it has also been used for book binding. Chrome-tanned leather, invented in 1858, is tanned using chromium sulfate and other salts of chromium. It is more supple and pliable than vegetable-tanned leather, and does not discolor or lose shape as drastically in water as vegetable-tanned. It is also known as wet-blue for its color derived from the chromium. More esoteric colors are possible using chrome tanning.

Aldehyde-tanned leather is tanned using glutaraldehyde or oxazolidine compounds. This is the leather that most tanners refer to as wet-white leather due to its pale cream or white color. It is the main type of leather used in chrome-free leather often seen in infant's shoes and in automobiles made with chrome-free leather. Formaldehyde tanning (being phased out due to its danger to workers and the sensitivity of many people to formaldehyde) is another method of aldehyde tanning. Brain-tanned leathers fall into this category and are exceptionally water absorbent. Brain tanned leathers are made by a labor-intensive process which uses emulsified oils, often those of animal brains. They are known for their exceptional softness and their ability to be washed. Chamois leather also falls into the category of aldehyde tanning and like brain tanning produces a highly water absorbent leather. Chamois leather is made by using oils (traditionally cod oil) that oxidize easily to produce the aldehydes that tan the leather to make the fabric the color it is.

Synthetic-tanned leather is tanned using aromatic polymers such as the Novolac or Neradol types. This leather is white in color and was invented when vegetable tannins were in short supply, i.e. during the Second World War. Melamine and other amino-functional resins fall into this category as well and they provide the filling that modern leathers often require. Urea-formaldehyde resins were also used in this tanning method until dissatisfaction about the formation of free formaldehyde was realized.

Alum-tanned leather is tanned using aluminium salts mixed with a variety of binders and protein sources, such as flour, egg yolk, etc. Purists argue that alum-tanned leather is technically "tawed" and not tanned, as the resulting material will rot in water. Very light shades of leather are possible using this process, but the resulting material is not as supple as vegetable-tanned leather.

Rawhide is made by scraping the skin thin, soaking it in lime, and then stretching it while it dries. Like alum-tanning, rawhide is not technically "leather", but is usually lumped in with the other forms. Rawhide is stiffer and more brittle than other forms of leather, and is primarily found in uses such as drum heads where it does not need to flex significantly; it is also cut up into cords for use in lacing or stitching, or for making many varieties of dog chews.

Today, most leather is made of cattle skin, but many exceptions exist. Lamb and deer skin are used for soft leather in more expensive apparels. Deer and elk skin are widely used in work gloves and indoor shoes. Pigskin is used in apparel and on seats of saddles.

Kangaroo skin is used to make items which need to be strong but flexible, it is the material most commonly used in high quality bullwhips. Kangaroo leather is favored by some motorcyclists for use in motorcycle leathers specifically because of its lighter weight and higher abrasion resistance compared with cowhide, thus providing greater protection in case of a fall on the roadway. Kangaroo leather is also used for high performance soccer footwear.

Leather made from more exotic skins has at different times in history been considered very beautiful. For this reason certain snakes and crocodiles have been hunted to near extinction.

In the 1970s, ostrich farming for their feathers became popular, and ostrich leather became available as a side product. There are different processes to produce different finishes for many applications, i.e., upholstery, footwear, automotive products, accessories and clothing. Ostrich leather is considered one of the finest and most durable in the world and is currently used by many major fashion houses such as Hermès, Prada, Gucci, and Louis Vuitton. Ostrich leather has a characteristic "goose bump" look because of the large follicles from which the feathers grew. In Thailand, sting ray leather is used in wallets and belts in the same way as regular bovine leather. Sting ray leather is as tough and durable as hard plastic.

In Amtgard

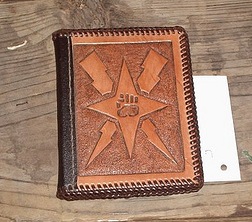

In Amtgard leather is is used to create many of the things we use on a day to day basis. Belts are typically made of leather, although they can be woven. Armor, shoes, garb, Quiver, Shield Covers and belt pouches can also made with leather. It is a common feature to Arts and Sciences competitions. Tooling leather is particularly popular.

Leather Crafts

- Leather Tooling

- Leather Applique

- Leather Molding

- Leather Garments

- Shoes

- Cuir Bouilli

- Leather Gloves

- Leather Armor

Links

Resources

- IILG International Internet Leathercrafters Guild - Excellent resource. Membership fee required for use of most resources.

- LeatherWorker.Net A forum covering everything leatherwork related. User account required to view pictures or make posts, but membership is free.

Supplies

- Tandy Leather - Online and locally in many places. Beginner videos available on their website.

- Springfield Leather - Online ordering or local to Springfield, MO.

- HideCrafter - Online ordering or local to Fort Worth, TX.

- Ostrich Market - Online ordering or local to Melbourne, FL. An excellent place for exotic hides at good prices.

- Brettun's Leather - Online only, they have great leather at cheap prices, and free shipping.

Check out the Amtgard Resources page for more information.