Difference between revisions of "Riveted Chainmail (V7)"

(New page: ===A type of Armor=== ====According to the Rulebook==== "chain in which all the links have been individually riveted together." This armor is worth a base of 4 Armor Points. [...) |

|||

| Line 1: | Line 1: | ||

===A type of [[Armor]]=== | ===A type of [[Armor]]=== | ||

====According to the [[Rulebook]]==== | ====According to the [[Rulebook]]==== | ||

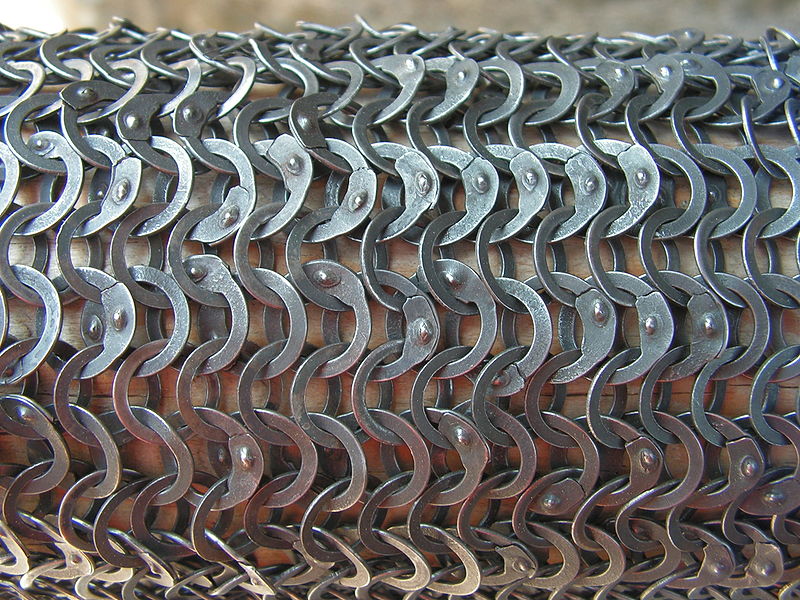

| + | [[Image:800px-Chainmail detail.jpg|thumb|Example of modern riveted mail]] | ||

"chain in which all the links have been individually riveted together." This armor is worth a base of 4 [[Armor Points]]. | "chain in which all the links have been individually riveted together." This armor is worth a base of 4 [[Armor Points]]. | ||

| + | ===Riveted Mail=== | ||

| + | Several patterns of linking the rings together have been known since ancient times, with the most common being the 4-to-1 pattern (where each ring is linked with four others). In Europe, the 4-to-1 pattern was completely dominant. Mail was also common in East Asia, primarily Japan, with several more patterns being utilised and an entire nomenclature developing around them. | ||

| + | Historically, in Europe, from the pre-Roman period on, the rings composing a piece of mail would be riveted closed to reduce the chance of the rings splitting open when subjected to a thrusting attack or a hit by an arrow. | ||

| + | Up until the 14th century European mail was made of alternating rows of both riveted rings and solid rings. After that it was almost all made from riveted rings only. Both would have been made using wrought iron. Some later pieces were made of wrought steel with an appreciable carbon content that allowed the piece to be heat treated. Wire for the riveted rings was formed by either of two methods. One was to hammer out wrought iron into plates and cut or slit the plates. These thin pieces were then pulled through a draw-plate repeatedly until the desired diameter was achieved. Waterwheel powered drawing mills are pictured in several period manuscripts. Another method was to simply forge down an iron billet into a rod and then proceed to draw it out into wire. The solid links would have been made by punching from a sheet. Forge welding was also used to create solid links, but the only known example from Europe is that of the 7th century Coppergate mail drape. Outside of Europe this practice was more common such as the well known "theta" links from India. | ||

[[category:Rulebook Terms]] | [[category:Rulebook Terms]] | ||

Revision as of 17:18, 13 November 2008

A type of Armor

According to the Rulebook

"chain in which all the links have been individually riveted together." This armor is worth a base of 4 Armor Points.

Riveted Mail

Several patterns of linking the rings together have been known since ancient times, with the most common being the 4-to-1 pattern (where each ring is linked with four others). In Europe, the 4-to-1 pattern was completely dominant. Mail was also common in East Asia, primarily Japan, with several more patterns being utilised and an entire nomenclature developing around them. Historically, in Europe, from the pre-Roman period on, the rings composing a piece of mail would be riveted closed to reduce the chance of the rings splitting open when subjected to a thrusting attack or a hit by an arrow.

Up until the 14th century European mail was made of alternating rows of both riveted rings and solid rings. After that it was almost all made from riveted rings only. Both would have been made using wrought iron. Some later pieces were made of wrought steel with an appreciable carbon content that allowed the piece to be heat treated. Wire for the riveted rings was formed by either of two methods. One was to hammer out wrought iron into plates and cut or slit the plates. These thin pieces were then pulled through a draw-plate repeatedly until the desired diameter was achieved. Waterwheel powered drawing mills are pictured in several period manuscripts. Another method was to simply forge down an iron billet into a rod and then proceed to draw it out into wire. The solid links would have been made by punching from a sheet. Forge welding was also used to create solid links, but the only known example from Europe is that of the 7th century Coppergate mail drape. Outside of Europe this practice was more common such as the well known "theta" links from India.